Product Excellence GRI G4 EN27 PR3

We are committed to bringing products into consumers’ homes that exceed expectations, while significantly improving our own environmental performance to create positive, meaningful change.

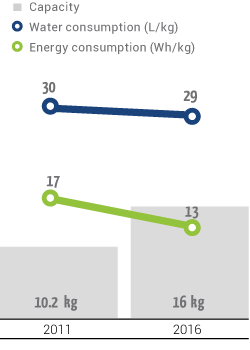

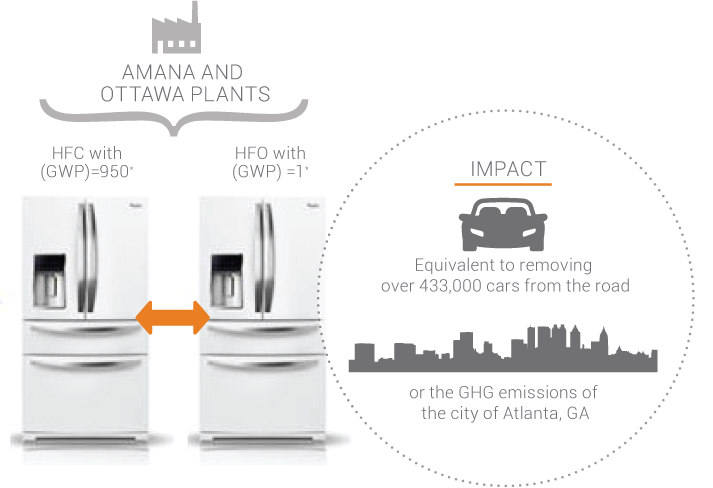

We have designed and produced a number of new water and energy-efficient products. Our commitment to improve lives and make a positive impact, while we work to reduce our environmental footprint, is important to us. Our products have consistently improved over time, especially in the largest impact area: their energy and water consumption during use. We are committed to saving precious resources while realizing cost savings for consumers. We will continue to increase our use of renewable energy and lower-impact materials. This will directly impact the communities in which we operate and benefit our consumers, no matter where they are around the globe.

AHAM Sustainability Standards — We continue to earn certifications as new sustainability standards are published by the Association of Home Appliance Manufacturers (AHAM). In February 2015, AHAM released a new standard for cooking products. In 2015, we announced that nine of Whirlpool Corporation’s products were among the industry’s first certified under the AHAM Sustainability Standards for Cooking Products. Seven ranges and two built-in ovens were certified. We maintain certifications to the completed standards for refrigerators/freezers and clothes washers. So far, we have certified more products to the new sustainability standards than any other appliance manufacturer (13 refrigerator/freezer models certified, eight front-load washers, and 10 top-load washers). We were the first to certify refrigerators/freezers and top-load clothes washers.